Detroit Diesel Series 60 Jake Brake Torque Specs

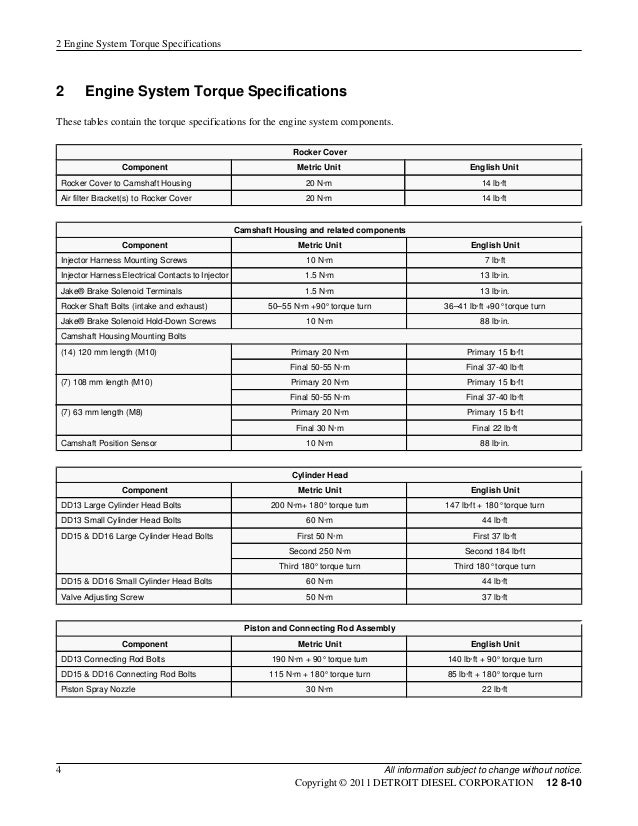

The oil pan bolt torque specifications, of a series 60 Detroit diesel engine, is 40 pounds. The bolts should be tighten by alternating end to end and side to side. 0 0 1 Detroit Diesel Series 60 Cylinder Head Bolts Prior to 2002 torque = 250 - 285 Nm, 184 - 210 lb.ft After 2002 torque = 298 Nm, 220 lb.ft Torque Specifications. Effective August 10, 2000, Model 795 Jake Brakes are used on all Series 60 engines requiring an engine brake. Former Jake Brake production models for the Series 60 engine were the 760A (which replaced model 760), 760B, 765, 765A, 770 and 790. Detroit Diesel engine model Nos. 6067GU28 and 6067GK28 are for bus/coach applications. Specifications for 1988-2007 Detroit Diesel 60-Series diesel engines. Camshaft timing, valve lash, injector height, and Jake Brake® lash are all very important specifications that must be followed closely in order to optimize the performance and service life of any Detroit Diesel engine.

Section 1.36

Jake Brake

The engine brake has been designed to fit on the Series 60 engine with no additional valve cover spacers. There are three styles of valve covers for the Series 60 engine. On engines equipped with a two-piece aluminum valve cover, it is NOT necessary to remove the lower valve cover to install the engine brake. However, one style of upper valve cover may require modification at the breather housing location (inside) for engine brake clearance.

The model, part number and serial number are located on the nameplates at the top of each housing. See Figure 'Nameplate Location on Housing' .

1. Identification Plate |

Detroit Diesel Series 60 Jake Brake Torque Specs 2010 Sonata

Figure 1. Nameplate Location on Housing

NOTICE: |

Only the specific brake model can be used with the engine model it was designed for. Also, the correct slave piston adjustment specification must be used. Failure to follow these instructions may result in serious engine or engine brake damage. |

Listed in Table 'Jake Brake Model Information' are the different Jake Brake models used and the slave piston adjustment specification.

Model Number | Model Year | Engine Displacement | Engine Brake | Slave Piston Adjustment |

6067WU40 | Pre-1991 | 11.1L | 760/760A | 0.660 mm (0.026 in.) |

6067GU40 | Pre-1991 | 12.7L | 760/760A | 0.508 mm (0.020 in.) |

6067WU60 | 1991 | 11.1L | 760/760A | 0.660 mm (0.026 in.) |

6067GU40 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GU28 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GU91 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067WK60 | 1994 | 11.1L | 760A | 0.660 mm (0.026 in.) |

6067GK60 | 1994 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GK28 | 1994 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067EK60 | 1998 | 11.1L | 760B | 0.584 mm (0.023 in.) |

6067PK60 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067TK60 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067TK45 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067MK60 | 1998 | 12.7L | 770 | 0.584 mm (0.023 in.) |

6067BK60 | 1998 | 12.7L | 770 | 0.584 mm (0.023 in.) |

6067HKXX | 1998 (Non-Line Haul) | 14L | 770 | 0.584 mm (0.023 in.) |

6067MK28, 6067MK45, 6067MK57, 6067MK60 | 2000 | 12.7L Standard | 790 | 0.660 mm (0.026 in.) |

6067BK28, 6067BK45, 6067BK57, 6067BK60 | 2000 | 12.7L Premium | 790 | 0.660 mm (0.026 in.) |

6067HK45, 6067HK60 | 2000 | 14L U.S. | 790A | 0.660 mm (0.026 in.) |

6067WK28, 6067WK60 | 2000 | 11.1L | 790B | 0.660 mm (0.026 in.) |

6067LK28, 6067LK45, 6067LK60 | 2000 | 11.1L | 790B | 0.660 mm (0.026 in.) |

6067GK28, 6067GK45, 6067GK91, 6067PK62, 6067TK28, 6067TK60, 6067TK62 | 2000 | 12.7L | 790B | 0.660 mm (0.026 in.) |

6067HK62 | 2000 | 14L Australian | 790C | 0.660 mm (0.026 in.) |

6067MK28, 6067MK45, 6067MK57, 6067MK60 | 2000 | 12.7L Standard | 795 | 0.813 mm (0.032 in.) |

6067BK28, 6067BK45, 6067BK57, 6067BK60 | 2000 | 12.7L Premium | 795 | 0.813 mm (0.032 in.) |

6067HK45, 6067HK60 | 2000 | 14L U.S. | 795 | 0.813 mm (0.032 in.) |

6067WK28, 6067WK60 | 2000 | 11.1L | 795 | 0.813 mm (0.032 in.) |

6067LK28, 6067LK45, 6067LK60 | 2000 | 11.1L | 795 | 0.813 mm (0.032 in.) |

6063GK60, 6067GK28, 6067GK45, 6067GK91, 6067PK62, 6067TK28, 6067TK60, 6067TK62 | 2000 | 12.7L | 795 | 0.813 mm (0.032 in.) |

6067HK62 | 2000 | 14L Australian | 795 | 0.813 mm (0.032 in.) |

All slave piston adjustments shown here are current as of the date of this manual and supersede all previous adjustments.

XXXX = Model numbers to be determined.

Note: All engines built after serial number 06R0004455 have the correct engine parts for engine brake installation. The model numbers have changed because of design changes in the engine brakes.

Note: All Series 60 engines with serial numbers 06R0004455 or higher are Jake Brake ready. Do not install a Jake Brake on engines with lower serial numbers.

Effective August 10, 2000, Model 795 Jake Brakes are used on all Series 60 engines requiring an engine brake.

Former Jake Brake production models for the Series 60 engine were the 760A (which replaced model 760), 760B, 765, 765A, 770 and 790.

Detroit Diesel engine model Nos. 6067GU28 and 6067GK28 are for bus/coach applications. Due to interference fits on some coach chassis, a two-housing Jake Brake kit may be required. Contact your Detroit Diesel Distributor for information on these kits.

Detroit Diesel Series 60 Jake Brake Torque Specs List

Jake Brake® is a registered trademark of Jacobs Vehicle Systems. J-Lash™ is a trademark of Jacobs Vehicle Systems.

Energizing the engine brake effectively converts a power-producing diesel engine into a power-absorbing air compressor. This is accomplished through motion transfer using a master-slave piston arrangement which opens cylinder exhaust valves near the top of the normal compression stroke, releasing the compressed cylinder charge to exhaust. See Figure 'Jake Brake Schematic' .

1. Exhaust Valve | 7. Oil In |

2. Slave Piston Assembly | 8. Check Valve (Model 760) |

3. Exhaust Valve | 9. Solenoid Valve |

4. Leveling Screw | 10. Control Valve |

5. Slave Piston Adjusting Screw | 11. Master Piston |

6. Accumulator | 12. Injector Pin and Roller |

Figure 2. Jake Brake Schematic

The blowdown of compressed air to atmospheric pressure prevents the return of energy to the engine piston on the expansion stroke, the effect being a net energy loss, since the work done in compressing the cylinder charge is not returned during the expansion process.

Exhaust blowdown occurs as the energized solenoid valve permits engine lube oil to flow under pressure through the control valve to both the master piston and the slave piston. See Figure 'Jake Brake Schematic' .

Oil pressure causes the master piston to move down, coming to rest on the injector rocker arm roller.

The injector rocker arm begins its travel as in the normal injection cycle, moving the master piston upward and directing high-pressure oil to the slave piston. The ball check valve in the control valve traps high-pressure oil in the master-slave piston system.

High pressure oil causes the slave piston to move down, momentarily opening the exhaust valves, while the engine piston is near its top-dead-center position, releasing compressed cylinder air to the exhaust manifold.

At the bottom of its stroke, the slave piston separates from the valve in the slave piston adjusting screw, allowing high pressure oil to flow into the accumulator. This reduces the pressure in the high pressure circuit, permitting the slave piston to retract and the exhaust valves to close in preparation for the normal exhaust valve cycle. The oil pressure reserved in the accumulator ensures that the hydraulic circuit is fully charged for the next cycle. Compressed air escapes to the atmosphere, completing a compression braking cycle.

The Jake Brake is electronically controlled. Jake Brake control system wiring will vary depending on the vehicle manufacturer. For a general overview of the Jake Brake, see Figure 'Typical Model 760, 765, or 770 Jake Brake Assembly' and see Figure 'Typical Model 790/795 Jake Brake Assembly' .

1. Ball Check Valve (Model 760 Only) | 8. Control Valve Spring | 15. Power Lash Assembly |

2. Washer | 9. Collar Spring | 16. Slave Piston Adjusting Screw |

3. Master Piston | 10. Washer | 17. Slave Piston |

4. Master Piston Spring | 11. Snap Ring Retainer | 18. Slave Piston Leveling Screw |

5. Washer and Screw Assembly | 12. Solenoid Valve | 19. Bridge |

6. Control Valve | 13. Seal Rings | 20. Return Spring |

7. Collar | 14. Accumulator Piston | 21. Screw |

Figure 3. Typical Model 760, 765, or 770 Jake Brake Assembly

1. Solenoid Valve | 9. Master Piston Retaining Ring | 17. Slave Piston |

2. Solenoid Upper Seal Ring | 10. Control Valve | 18. Slave Piston Bridge |

3. Solenoid Center Seal Ring | 11. Outer Control Valve Spring | 19. Outer Slave Piston Spring |

4. Solenoid Lower Seal Ring | 12. Inner Control Valve Spring | 20. Inner Slave Piston Spring |

5. Master Piston | 13. Control Valve Cover | 21. Spacer Tube |

6. Master Piston Pushrod | 14. Retaining Ring | 22. Shoulder Bolt |

7. Master Piston Spring | 15. Adjusting Screw* | 23. Drive Screw |

8. Master Piston Retainer | 16. Locknut | 24. Wire Harness Clip |

*Note that Model 790 Jake Brake uses a J-Lash™ assembly. Model 795 Jake Brake uses a solid screw.

Figure 4. Typical Model 790/795 Jake Brake Assembly

NOTICE: |

This application and adjustment information must be strictly followed. Failure to follow these instructions may result in serious engine or engine brake damage. |

Section 1.36.1

Repair or Replacement of Jake Brake®

To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 'Jake Brake® Repair or Replacement Flowchart' .

Figure 5. Jake Brake® Repair or Replacement Flowchart

Section 1.36.2

Removal of Model 760, 765, or 770 Jake Brake

Remove the model 760, 765, or 770 Jake Brake as follows:

Note: The following procedures apply to Model 760, 765, and 777 Jake Brake. For Model 790/795 Jake Brake removal procedures, refer to '1.36.6 Removal of Model 790/795 Jake Brake Assembly'.

PERSONAL INJURY |

To avoid injury, never remove any engine component while the engine is running. |

- Disconnect starting power for engine. Refer to OEM guidelines.

- Remove the engine rocker cover. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' for one-piece, refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' for two-piece and refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' for three-piece.

Note: If the engine is equipped with an aluminum two-piece valve cover, remove only the upper valve cover when installing the engine brake.

- Note the location of the rocker arm shaft, the exhaust valve rocker arm, the fuel injector rocker arm, and the intake valve rocker arm.

- Disconnect the solenoid wiring harness connectors from the engine brake solenoids. See Figure 'Jake Brake Assembly' .

1. Cylinder Head

4. Washers (3 each)

2. Jake Brake Assembly

5. Capscrews (3 each)

3. Solenoid

6. Engine Brake Harness

Figure 6. Jake Brake Assembly

- Remove the nine capscrews and washers that secure the engine brake assemblies to the cylinder head. See Figure 'Jake Brake Assembly' .

Note: Only the Model 760 Jake Brake uses two different length capscrews. Six bolts, 120 mm (4.72 in.) long, are used on the exhaust side of the engine. Three bolts, 110 mm (4.33 in.) long, are used on the intake side of the engine. These bolts must be reinstalled in their correct positions.

- Remove the engine brake assemblies and the spacer bar.

Section 1.36.3

Disassembly of Model 760, 765, or 770 Jake Brake

Remove the control valve as follows:

EYE INJURY |

To avoid injury from flying parts when working with components under spring tension, wear adequate eye protection (face shield or safety goggles). |

- Press down on control valve washer using an appropriate diameter rod to relieve spring pressure. See Figure 'Relieving Spring Pressure' .

1. Jake Brake Assembly

3. Snap Ring Retainer

2. Spring

4. Snap Ring Pliers

Figure 7. Relieving Spring Pressure

- Using retaining ring pliers, remove retaining ring.

- Slowly remove cover until spring pressure ceases, then remove the two control valve springs and collar. See Figure 'Removing Control Valve Springs and Collar' .

1. Jake Brake Assembly

5. Washer

2. Control Valve

6. Collar Spring

3. Collar

7. Control Valve Spring

4. Snap Ring Retainer

Figure 8. Removing Control Valve Springs and Collar

- Using needle-nose pliers, reach into the bore and grasp the stem of the control valve. Remove control valve.

Remove the slave piston adjusting screw as follows:

- Loosen slave piston adjusting screw locknut.

- Remove adjusting screw from housing. See Figure 'Removing Slave Piston Adjusting Screw' .

1. Jake Brake Assembly

2. Slave Piston Adjusting Screw

Figure 9. Removing Slave Piston Adjusting Screw

Remove the solenoid valve as follows:

NOTICE: |

To avoid possible engine damage, do not disassemble or tamper with the solenoid valve. |

- Disconnect solenoid valve harness.

- Using a 7/8 in. socket and extension for former solenoids or a 3/4 in. 6 point socket and extension for current solenoids, unscrew solenoid valve.

- Remove and discard the three rubber seal rings. See Figure 'Removing Rubber Seal Rings' .

1. Seal Rings (3)

2. Solenoid

Figure 10. Removing Rubber Seal Rings

- If the lower ring stays in the bottom of the housing bore, remove with a piece of wire.

Remove the accumulator as follows:

EYE INJURY |

To avoid injury from flying parts when working with components under spring tension, wear adequate eye protection (face shield or safety goggles). |

- Push down on the accumulator cover using the appropriate diameter rod, and remove the retaining ring. See Figure 'Removing Retaining Ring' .

1. Jake Brake Assembly

3. Retaining Ring Pliers

2. Retaining Ring

Figure 11. Removing Retaining Ring

- Relieve pressure on the accumulator cover.

- Remove the cover and spring.

- Use a magnet to remove the piston from the accumulator bore. See Figure 'Removing Piston from Accumulator Bore with Magnet' .

1. Jake Brake Assembly

4. Retaining Ring

2. Piston

5. Washer

3. Spring

Figure 12. Removing Piston from Accumulator Bore with Magnet

Remove the master piston as follows:

- Remove the screw, washer, and master piston spring from the housing.

- Remove the master piston. See Figure 'Removing the Master Piston' .

Note: Use needle-nose pliers, if necessary.

1. Washer and Screw Assembly

3. Master Piston

2. Jake Brake Assembly

4. Master Piston Spring

Figure 13. Removing the Master Piston

On Model 760 only, remove the ball check valve as follows:

- Remove the plug.

- Remove the ball check valve and spring.

Remove the slave piston as follows:

- Remove the screw and washer that retains the slave piston return spring.

- Remove the bridge and the slave piston. See Figure 'Removing Bridge and Slave Piston' .

1. Slave Piston Bridge

4. Return Spring

2. Jake Brake Housing

5. Washer

3. Slave Piston

6. Screw

Figure 14. Removing Bridge and Slave Piston

- Loosen the leveling screw locknut and remove the leveling screw from the bridge. See Figure 'Removing the Leveling Screw from the Bridge' .

1. Slave Piston Bridge

2. Slave Piston Leveling Screw

Figure 15. Removing the Leveling Screw from the Bridge

The injector rocker arm contains a pin and roller for actuating the engine brake master piston. If excessive wear or damage to the roller is present, replace the rocker arm assembly. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' .

Section 1.36.3.1

Cleaning of Model 760, 765, or 770 Jake Brake

Clean the Jake Brake as follows:

Note: Use an OSHA-approved cleaning solvent when washing parts. Be sure to coat parts with clean engine oil when reinstalling them.

- Wash the control valves with approved cleaning solvent.

- Push a wire through the hole in the base of the valve to the distance required to ensure that the ball check is free.

Note: The ball should lift with light pressure on the wire.

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- Dry the valve with compressed air, and wipe clean with a paper towel.

- Thoroughly clean the control valve bore in the housing using clean paper towels.

- Clean slave piston adjusting screw in an approved cleaning solvent.

- Clean out the solenoid valve bore in the housing.

NOTICE:

Use clean paper towels to clean the solenoid valve bore. Never use rags, as they may leave lint and residue which can plug the oil passageways, causing Jake Brake malfunction.

- Clean the master piston in approved cleaning solvent.

Section 1.36.3.2

Inspection of Model 760, 765, or 770 Jake Brake

The Jacobs engine brake is typically a trouble-free device. However, inspections are necessary and some maintenance is required. Use the following procedures to keep the engine brake in top condition.

Inspect the Jake Brake as follows:

- Inspect slave piston adjusting screw for protrusion, spring pressure and freedom of movement.

Note: The plunger should protrude from the bottom of the screw, have light spring pressure apparent when depressed, and move freely. Be sure the retaining ring is fully engaged in its groove (groove is located on the bottom of the reset screw and top of the POWER-LASH assembly).

- If the plunger does not protrude, the spring does not have light pressure or does not move freely, replace the entire screw assembly. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake'

- If the slave piston adjusting screw meets specifications, continue with inspection.

- Inspect the accumulator for wear or damage.

- If worn or damaged, replace the accumulator. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If accumulator is not worn or damaged, continue with inspection.

- Inspect the master piston bore for wear or damage.

Note: Some wear marks are permissible.

- If worn or damaged, replace the master piston. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If not worn or damaged, continue with inspection.

- Apply clean lube oil to the piston, and insert into bore.

Note: Master piston should move in and out freely with no binding.

- If binding occurs, replace master piston and/or housing. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If no binding occurs, continue with inspection.

- Inspect master piston spring for relaxation.

Note: The spring should hold the master piston completely in the housing.

- If relaxed, replace the spring. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If spring holds tightly, continue with inspection.

- Inspect the ball check valve (Model 760 only) for wear or damage.

- If worn or damaged, replace ball check valve. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If not worn or damaged, proceed with inspection.

- Inspect slave piston components for excessive wear or damage.

- If worn or damaged, replace slave piston component.

- If not worn or damaged, proceed with inspection.

Section 1.36.3.3

Inspection of Control Valve

Inspect the control valve as follows:

- Dip the control valves in clean lube oil.

- Holding the control valve by the stem, let it drop into the bore.

- If binding occurs or if the ball sticks in the valve, replace the control valve. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If no binding occurs and the ball does not stick in the control valve, assemble the Jake Brake. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

Section 1.36.4

Assembly of Model 760, 765, or 770 Jake Brake

Install the control valve as follows:

- Slip the control valve into the bore. See Figure 'Installing the Control Valve' .

Note: Make sure the control valve collar is installed with the longer sleeve area facing up. If the collar is installed upside down, the engine brake cylinder will not operate.

1. Jake Brake Assembly

5. Washer

2. Control Valve

6. Collar Spring

3. Collar

7. Control Valve Spring

4. Snap Ring Retainer

Figure 16. Installing the Control Valve

- Install the control valve collar and two springs.

Note: Ensure the collar is installed with the longer sleeve area facing up. If the collar is installed upside down, the engine brake cylinder will not operate.

- Press the cover (washer) into place.

- While holding the cover tightly in place, install the retaining ring.

- Rotate retaining ring ears 90 degrees to assure ring is seated in groove.

Install the slave piston adjusting screw as follows:

- Place the screw in the housing. See Figure 'Installing the Slave Piston Adjusting Screw' .

1. Jake Brake Assembly

2. Slave Piston Adjusting Screw

Figure 17. Installing the Slave Piston Adjusting Screw

- Torque the slave piston adjusting screw locknut to 35 N·m (25 lb·ft).

Install the solenoid valve as follows:

Note: As of October 19, 1997, former solenoids have been replaced with the current improved solenoids. The current solenoids have an increased installation torque and improved durability. The current solenoid is interchangeable with the former.

- Coat new solenoid valve seal rings with clean lube oil.

Note: Use current upper seals when installing current solenoids. New seals are identified with yellow stripes.

- Install the upper and center seal rings on the solenoid valve body and the lower seal ring into the bottom of the bore in the housing. See Figure 'Installation of Solenoid Valve Seal Rings' .

1. Seal Rings (3)

2. Solenoid

Figure 18. Installation of Solenoid Valve Seal Rings

- Make sure the seals are seated properly.

- Using a 7/8 in. socket and extension for former solenoids or a 3/4 in., 6 point socket and extension for current solenoids, carefully screw the solenoid valve into the housing without unseating the seals.

- Torque the former solenoid to 12.4 N·m (9 lb·ft). Torque the current solenoid to 20 N·m (15 lb·ft.)

Note: Be careful not to twist the seals while installing.

Install the accumulator as follows:

- Place the piston into the accumulator bore.

- Insert the spring, and install the cover.

- Push down the accumulator cover, and insert retaining ring.

Install the master piston as follows:

- Apply clean lube oil to the piston.

- Insert master piston into bore. See Figure 'Inserting Master Piston into Bore' .

1. Washer and Screw Assembly

3. Master Piston

2. Jake Brake Assembly

4. Master Piston Spring

Figure 19. Inserting Master Piston into Bore

- Install spring, washer, and screw.

Note: Make sure spring legs are centered around master piston boss.

- Torque screw to 10 N·m (7.4 lb·ft).

On model 760 only, install the ball check valve as follows:

- Install the ball check valve and spring. See Figure 'Installation of Ball Check Valve' .

1. Ball Check Valve

3. Pipe Plug

2. Spring

Figure 20. Installation of Ball Check Valve

- Insert the plug. Torque pipe plug to 11.2 N·m (8.3 lb·ft).

Install the slave piston as follows:

- Install the screw from the slave piston side of the bridge.

- Install the leveling screw locknut.

- Install the bridge with the leveling screw toward the center of the housing. See Figure 'Installing Bridge with Leveling Screw Toward Center of Housing' .

1. Washer

4. Bridge Assembly

2. Screw

5. Jake Brake Housing

3. Torsion Spring

Figure 21. Installing Bridge with Leveling Screw Toward Center of Housing

- Install the slave piston assembly torsion spring with the ends over the bridge. See Figure 'Installing the Slave Piston Assembly Torsion Spring' .

Figure 22. Installing the Slave Piston Assembly Torsion Spring

- Install the screw and washer over the center part of the spring.

NOTICE:

While tightening the screw on the torsion spring, push the spring toward the slave piston assembly. Failure to do so may result in contact between the intake valve adjusting screw and torsion spring. Serious engine damage may result.

- Torque the screw to 20 N·m (15 lb·ft.).

- Torque the slave piston leveling screw locknut to 47 N·m (35 lb·ft.).

Section 1.36.5

Installation of Model 760, 765, or 770 Jake Brake

Install the model 760, 765, or 770 Jake Brake as follows:

Note: The following procedures apply to Model 760, 765, and 770 Jake Brake. For Model 790/795 Jake Brake installation procedures, refer to '1.36.8 Installation of Model 790/795 Jake Brake Assembly'.

- Adjust the intake and exhaust valve clearances and set the injector heights. Refer to '13.2 Valve Lash, Injector Height (Timing) and Jake Brake® Lash Adjustments' .

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- Attach the length of tubing to a blow gun nozzle, and blow out the oil from the bolt holes.

- Cover the holes with hand towels to minimize oil spray.

Note: Removing the oil from the bolt holes prevents the cylinder head from cracking when tightening the bolts.

- Place the spacer bar on the exhaust manifold side of the cylinder head with the 'OUT' markings adjoining each other and facing the exhaust manifold. See Figure 'Spacer Bars with 'Out' Marks Adjoined' , and see Figure 'Location of Spacer Bars' .

Figure 23. Spacer Bars with 'Out' Marks Adjoined

Figure 24. Location of Spacer Bars

- Place the three engine brake housings over the rocker shafts with the solenoid valves toward the camshaft side of the engine.

Note: Be sure housings do not interfere with wiring harness.

LOSS OF BRAKING

To avoid injury from the loss of braking control due to an improperly installed engine brake, do not mix rocker arm shaft and engine brake mounting bolts.

NOTICE:

Do not mix the rocker arm shaft bolts and the Jake Brake capscrews. If the rocker arm shaft bolt is mistakenly used to mount the Jake Brake housing, the longer shoulder on the bolt will block the oil supply to the Jake Brake on the camshaft side of the housing. The brake will not retard the engine as designed. This condition could cause vehicle damage.

Note: The rocker arm shaft capscrew and Jake Brake capscrew, part of the Jake Brake assembly, are similar in appearance. Both are M12 x 110 mm (4.33 in.) long and have 12–point heads.

Note: In the event of a housing hold down bolt failure on a Jacobs engine brake housing, replace all bolts on that particular housing.

NOTICE:

Use bolts that have the Jacobs logo, circled 'J'. Installation of bolts that do not have the circled 'J' may result in damage to the engine, engine brake or both.

- The Jake Brake bolt has the Jacobs logo (circled 'J') and the letters 'EF' marked on the head. The bolt length is no longer marked atop the bolt head.

- The DDC rocker arm shaft bolt has the DDC logo (spinning arrows) and the vendor I.D. (F-C) on its head.

- Jake Brake model 760 requires two bolts along with one bolt and new washers.

- The DDC bolt shoulder is much longer, 17.0 mm (0.669 in.) versus 4 mm (0.157 in.) than the Jake Brake bolt. See Figure 'Jake Brake and DDC Bolt Identification' .

Note: Be sure that only Jake Brake bolts, see Figure 'Jake Brake and DDC Bolt Identification' , are installed in the Jake Brake housing.

Figure 25. Jake Brake and DDC Bolt Identification

NOTICE:

The model 760 uses two lengths of capscrews. Six 120 mm bolts should be installed on the exhaust side of the engine. Three 110 mm bolts should be installed on the camshaft side of the engine. Failure to do so will result in engine damage.

- On model 760, install one washer onto each 120 mm (4.72 in.) bolt, and insert into brake housing on the exhaust manifold side (two per housing). See Figure 'Installation of Jake Brake Housing Bolts on Exhaust Manifold Side' .

1. Washer

2. Long Bolt

Figure 26. Installation of Jake Brake Housing Bolts on Exhaust Manifold Side

- On model 760, install one washer on the 110 mm (4.331 in.) bolt, and insert into brake housing at the camshaft side (one per housing). See Figure 'Installation of Jake Brake Housing Bolts on Camshaft Side' .

1. Jake Brake Housing Assembly

2. Capscrew

Figure 27. Installation of Jake Brake Housing Bolts on Camshaft Side

- On models 760A, 760B, 765, and 765A, lubricate each hold down bolt with clean engine oil.

Note: All the housing capscrews for these models are the same length of 110 mm (4.331 in.).

- On models 760A, 760B, 765, and 765A, install a washer on each bolt, and install into housings (three bolts per housing).

- On models 760A and 765, move the housing from side to side, and locate the housing in the center position of the movement. See Figure 'Locating Center Position of Housing' .

Figure 28. Locating Center Position of Housing

- On models 760B and 765A, move the housing from side to side, and locate as far toward the camshaft side of the engine as possible.

- On all models, torque the engine brake capscrews using the following sequence:

- Torque the three bolts on the camshaft side of the engine to 55 N·m (40 lb·ft).

- Torque the six bolts on the exhaust manifold side of the engine to 55 N·m (40 lb·ft).

- Repeat the tightening sequence and re-torque all bolts to 136 N·m (100 lb·ft).

- Check the torque to 136 N·m (100 lb·ft).

- Secure injector wire harness to each of the six Jake Brake spacer bars with tie straps.

- Verify tie strap is properly seated on the spacer bar. See Figure 'Injector Harness Tie Strap Location'

- Verify tie strap is tight on spacer bar and does not move.

- Clip excess tails from tie strap.

Note: Ensure all wires are away from moving parts.

1. Injector Harness

2. Tie Strap

3. Spacer Bar

Figure 29. Injector Harness Tie Strap Location

- Connect wiring harness solenoid connectors to solenoids. See Figure 'Jake Brake Wire Terminal Connection Identification'

Section 2.3

N2 Electronic Unit Injector

The N2 Electronic Unit Injector (EUI) is a lightweight, compact unit that injects diesel fuel directly into the combustion chamber. See Figure 'N2 Electronic Unit Injector Cross-section' .

1. Spray Tip | 11. Injector Body |

2. Spring Cage | 12. Plunger |

3. Check Valve Cage | 13. Upper O-ring Grooves and Seals |

4. Spacer | 14. Fuel Outlet Openings |

5. Fuel Inlet Opening | 15. Injector Nut |

6. Fuel Supply Chamber | 16. Lower O-rings Grooves and Seals |

7. Poppet Control Valve | 17. Flat Disk Check Valve |

8. Solenoid | 18. Injector Needle Valve Spring |

9. Injector Follower | 19. Needle Valve |

10. Injector Follower Spring | |

Figure 1. N2 Electronic Unit Injector Cross-section

The amount of fuel injected and the beginning of injection timing is determined by the ECM. The ECM sends a command pulse which activates the injector solenoid. The EUI performs four functions:

- Creates the high-fuel pressure required for efficient injection.

- Meters and injects the exact amount of fuel required to handle the load.

- Atomizes the fuel for mixing with the air in the combustion chamber.

- Permits continuous fuel flow for component cooling.

Engine combustion is obtained by injecting, under pressure, a small quantity of accurately metered and finely atomized fuel oil into the cylinder. Metering and timing of the fuel is accomplished by the ECM which actuates the solenoid poppet valve to stop the free flow of fuel through the injector. When the solenoid poppet valve closes, fuel is trapped in the injector body and under the plunger. The continuous fuel flow through the injector prevents air pockets in the fuel system and cools those injector parts subjected to high combustion temperatures.

Note: Do not test new or reliabilt® remanufactured electronic unit injectors prior to installation in the engine. The Kent-Moore® POP stand should only be used as a diagnostic tool on fuel injectors that have been removed from an engine.

Fuel enters the injector through the two fuel inlet filter screens located around the injector body. See Figure 'Fuel Injector Body' . Filter screens are used at the fuel inlet openings to prevent relatively coarse foreign material from entering the injector.

Figure 2. Fuel Injector Body

Note: Effective with September, 1988 production, Series 60 engine EUI nuts incorporate one upper seal ring groove and seal ring, instead of two. See Figure 'N2 Electronic Unit Injector' .

Outlet openings, through which the excess fuel oil returns to the fuel return manifold and then back to the fuel tank, are located around the injector nut. See Figure 'N2 Electronic Unit Injector' .

Figure 3. N2 Electronic Unit Injector

After entering the nut cavity, the fuel passes through a drilled passage into the poppet control valve and plunger area. See Figure 'N2 Electronic Unit Injector Cross-section' .

The plunger operates up and down in the body bore of the injector. The motion of the injector rocker arm is transmitted to the plunger and follower that bears against the follower spring.

As the piston moves approximately two-thirds of the way up in the cylinder on the compression stroke, the injector cam lobe begins to lift causing the injector rocker arm to push down on the follower and the plunger. Just before injection begins, the ECM sends an electronic pulse which turns on the injector solenoid. The energized solenoid creates a magnetic force which pulls the armature up, closing the poppet valve and trapping fuel under the plunger and passages leading down to the needle valve. The fuel pressure increases as the plunger continues its downward stroke.

A flat disk check valve is built into the injector fuel passages between the plunger and the tip. This check valve normally has no effect on the injection process but will function to prevent cylinder gases from blowing back into the injector and fuel system if a particle of debris should become lodged between the needle and seat or the tip assembly fails.

This fuel pressure acts on the needle valve. When it creates a force high enough to overcome the valve spring force holding the needle on its seat, the needle valve moves up, allowing the high pressure fuel to spray into the combustion chamber. The high pressure of the fuel passing through the small holes in the tip creates a finely atomized spray for combustion within the cylinder.

After the pulse width time has passed, the ECM turns off the current to the injector solenoid. The de-energized solenoid allows a spring to open the poppet valve, permitting the trapped fuel to spill down, dropping the pressure within the injector. When the pressure is low enough the needle valve closes and ends injection.

The beginning of injection and metering of the fuel in relation to the crankshaft position are controlled by the ECM. Injection begins soon after the poppet valve is closed. The valve closing point information, known as the response time feedback, is returned to the ECM. This information is used to monitor and adjust injection timing, thus removing injector-to-injector variation influences on timing. The amount of fuel injected depends on the pulse width stored in the calibration which determines how long the poppet valve remains closed; the larger the pulse width the longer the valve is closed and the more fuel is injected.

When the injector rocker arm has completed its downward travel the injector follower spring returns it to the starting position. As the plunger moves up fuel enters the injector pumping cavity for another injection cycle. The constant circulation of fuel through the injector renews the fuel supply in the chamber and aids the cooling of the injector.

Section 2.3.1

Repair or Replacement of N2 Electronic Unit Injector

To determine if repair is possible or replacement is necessary perform the following procedure. See Figure 'Flowchart for Repair or Replacement of N2 Electronic Unit Injector' .

Figure 4. Flowchart for Repair or Replacement of N2 Electronic Unit Injector

Section 2.3.2

Removal of N2 Electronic Unit Injector

The following steps must be performed prior to removing an injector:

Note: The solenoid can be replaced without removing the injector. Refer to '2.3.4 Repair of N2 Electronic Unit Injector Solenoid and Seals' .

- Clean the valve rocker cover around its seat on the head, and in the attaching bolt recesses.

- To remove the one-piece rocker cover, refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' .

- To remove the two-piecerocker cover, refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' .

- To remove the three-piece rocker cover, refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' .

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

NOTICE:

All the fuel must be removed from the cylinder head before removing an injector to prevent the fuel from entering the cylinder and causing hydrostatic lock or washdown. If the head is not thoroughly purged of fuel before an injector is removed, fuel remaining in the fuel manifold will drain into the cylinder filling the piston dome recess. It cannot drain from the dome and, if not removed, can cause hydrostatic lock and bend the connecting rod.

- Drain the cylinder head fuel gallery by removing the inlet and outlet lines from the fittings at the rear of the cylinder head. Blow low pressure compressed air into the inlet fitting for 20 to 30 seconds or until all of the fuel is purged from the cylinder head. See Figure 'Cylinder Head Fuel Fitting Locations' .

Note: Front and rear rocker shaft assemblies look identical but are not interchangeable because of different bolt hole center distances. The outboard end of each rocker shaft assembly is marked with the DDC logo for identification. Care should be taken to identify and return assemblies to the proper location if both overhead assemblies are removed.

Note: Loosening the fuel line at the inlet fitting will allow fuel to flow faster. Carefully collect the drained fuel in an appropriate container.

Figure 5. Cylinder Head Fuel Fitting Locations

- Remove the two rocker shaft through-bolts and one nut for each rocker shaft assembly, and lift the rocker shaft assembly off the engine. Refer to '1.3.2 Removal of Rocker Arm Assembly' .

To remove the injector, complete the following steps:

NOTICE: |

Do not remove the screws from the injector. The wire terminals have keyhole slots to fit over the screw head. Turning the screws too far will damage the threads in the injector solenoid housing. |

- Loosen the injector wire terminal screws two full turns and remove the terminal wires.

- Remove injector hold down clamp.

NOTICE:

Extreme care should be used when handling an EUI to avoid costly damage by dropping or otherwise mishandling the EUI.

Note: When replacing an EUI, always replace the injector O-rings.

- Lift the injector from its seat in the cylinder head by inserting a pry bar under the injector body. See Figure 'Removing N2 Electronic Unit Injector' .

Figure 6. Removing N2 Electronic Unit Injector

NOTICE:

Avoid wire brushing the spray holes to prevent damage.

- Cover the injector hole in the cylinder head to keep out foreign material. Remove carbon from the injector exterior in the area where the tip joins the nut, using wire buffing wheel (J–7944) .

Section 2.3.3

Disassembly of Electronic Unit Injector

On a Series 60 engine EUI, only the injector solenoid and seal rings are serviceable. The injector must not be disassembled.

Section 2.3.3.1

Inspection of the N2 Electronic Unit Injector

To clean and inspect the injector, complete the following steps:

Note: The injector can be tested either on or off of the engine.

EYE INJURY |

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure. |

- Clean the exterior of the injector with clean solvent and dry it with compressed air.

Note: Do not test new or reliabilt® remanufactured electronic unit injectors prior to installation in the engine. The Kent-Moore® POP stand should only be used as a diagnostic tool on fuel injectors that have been removed from an engine.

- Test the EUI using J–34760–A . Follow procedures supplied with this tool. Reuse or replace injector or injector and solenoid as indicated by testing.

- Inspect the O-rings for damage or foreign material. Replace O-rings.

- Inspect the fuel injector tubes at the injector seat. If required, replace the fuel injector tubes.

Section 2.3.4

Repair of N2 Electronic Unit Injector Solenoid and Seals

Perform the following steps for solenoid replacement:

- Loosen the injector wire terminal screws two turns and remove terminal wires.

- Loosen four hex-head screws and remove old solenoid. See Figure 'Electronic Unit Injector Solenoid Assembly' .

1. Spacer Seals

4. Screw

2. Solenoid

5. Follower Retainer

3. Load Plate

6. Spacer

Figure 7. Electronic Unit Injector Solenoid Assembly

- Perform the appropriate step for the DDEC unit used.

- For DDEC I and DDEC II, discard the solenoid, load plate, follower retainer, and screws. Do not reuse old screws.

- For DDEC III/IV, discard the solenoid, follower retainer, and screws. Do not reuse old screws. The load plate must be reused.

NOTICE:

The spacer is a matched component with the armature and must remain with its respective injector.

- Remove spacer and seals from injector body.

- Discard seals, but do not discard spacer.

- Install new seal in spacer groove and position spacer on body with seal facing down. See Figure 'Electronic Unit Injector Solenoid Assembly' . Seal may be retained in groove with small quantity of grease.

- Install new seal in solenoid groove.

- Install solenoid on spacer.

NOTICE:

The load plate on each DDEC III injector is unique and must remain with the injector. The DDEC III load plate carries the injector part number, the injector serial number in bar code format, and the injector calibration code number.

- Install new screws through the load plate and follower retainer, solenoid, and spacer.

- Thread screws into body and tighten all screws until heads contact retainer and load plate with a slight force (less than 0.6 N·m [5.3 lb·in.] torque) in the sequence shown. See Figure 'N2 Electronic Unit Injector Solenoid Torque Sequence' .

Figure 8. N2 Electronic Unit Injector Solenoid Torque Sequence

- Torque screws to 2 N·m (17.7 lb·in.) in the sequence shown. See Figure 'N2 Electronic Unit Injector Solenoid Torque Sequence' .

- On DDEC II injectors only, etch the last four digits of injector part number on the load plate. See Figure 'N2 Electronic Unit Injector Solenoid Torque Sequence' .

Section 2.3.5

Installation of the N2 Electronic Unit Injector

Perform the following steps:

- If the fuel system is contaminated with coolant:

- Drain the fuel tanks and refill with clean fuel. Refer to '14.6.2 Fuel Tanks' .

- Replace both filters with new, and clean the fuel/water separator, if equipped. Refer to '14.6.13 Fuel Filters (Diesel)' .

- Inspect fuel injectors for damage and replace as required.

- If the coolant system is contaminated with fuel, flush and reverse flush the system. Refer to '14.6.4 Cooling System' .

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

NOTICE:

Leftover fuel must be removed from the injector bore before injector installation. If fuel is trapped between the top of the injector hole tube and the lower injector O-ring seal, it may seep down to the injector hole tube seal ring, causing swelling and possible seal leakage.

- Using clean compressed air, blow out any fuel remaining in the injector bore.

Note: If the engine is equipped with an auxiliary injector tube seal, replace it with a new seal when the injector is removed.

NOTICE:

Do not use a metal dowel as this may damage the seal.

NOTICE:

Injector seals are considered one-use items and cannot be reused. Any time an injector is removed, all three injector nut O-ring seals must be replaced with new seals. Failure to replace seals can result in seal leakage.

- Detroit Diesel encourages the use of an additional service seal (5104701) that is impervious to both coolant and fuel. This seal should be used in situations where injector tube seal leakage or deterioration is suspected or confirmed. Place the auxiliary seal in the injector hole and seat it against the top of the injector tube with a 41.3 mm (1-5/8 in.) diameter wood or plastic dowel.

- Check to make sure the injector bore is thoroughly clean.

- Apply a thin coat of clean ethylene glycol to the injector seal rings and install them in the injector nut ring grooves. Make sure seals are properly seated.

- Insert the injector into its respective injector tube bore. Visually align the injector body for equal clearance between valve springs (there is no locating dowel pin on the underside of the EUI). After locating the injector, press down on the top of the injector body with the heel of your hand to seat it in the injector tube.

Note: The injector tube bore should be cleaned and inspected for damage before installation of the electronic unit injector. Refer to '2.4.4 Cleaning of N2 Injector Tube' .

NOTICE:

The hemispherical portion of the hold-down clamp washers must be installed facing the clamp (pointing down) in order to prevent damage to the washers. See Figure 'N2 Electronic Unit Injector and Related Parts' .

1. Injector Hold-down clamp

5. Auxiliary Injector Seal

2. Electronic Unit Injector

6. Injector O-rings

3. Injector Tube O-ring

7. Hold-down Clamp Washer

4. Injector Tube

8. Hold-down Clamp Bolt

Figure 9. N2 Electronic Unit Injector and Related Parts

- Determine which type of hold-down clamp is used by measuring the overall height.

- If the overall height is 54 mm (2.125 in.), proceed to step 9 .

- If the overall height is 52 mm (2.047 in.), skip to step 10 .

- Position a 0.762 mm (0.030 in.) feeler gage between the clamp and injector spring on the side of the spring that faces the intake manifold.

- Install the hold-down clamp , hemispherical clamp washer (flat surface up against bolt) and hold-down bolt to the injector. See Figure 'Hold-down Clamp Washer Installation' . Ensure the clamp does not interfere with the injector spring or valve springs.

- Torque the hold-down bolt to 55-66 N·m (43-49 lb·ft).

Figure 10. Hold-down Clamp Washer Installation

- Install the EUI terminal wires by positioning the keyhole in the terminal over the screw in the injector solenoid housing. Pull the terminal end down so that the screw rests in the smaller slot in the terminal. Torque the terminal screws to 1.08–1.13 N·m (9.5–10.0 lb·in.). Do not bend the terminals down after installation. See Figure 'N2 Electronic Unit Injector Terminal Installation' .

Figure 11. N2 Electronic Unit Injector Terminal Installation

- Install the rocker arm shafts, with rocker arms in place. Refer to '1.3.3 Installation of Rocker Arm Shaft Assembly' .

Note: Front and rear rocker shaft assemblies look identical but are not interchangeable due to different bolt-hole center distances. The outboard end of each rocker shaft assembly is marked with the DDC logo for identification. Care should be taken to identify and return assemblies to the proper location if both overhead assemblies were removed.

- Adjust the intake and exhaust valve clearances and injector height. Refer to '13.2 Valve Lash, Injector Height (Timing) and Jake Brake® Lash Adjustments'

- Install the inlet and outlet fuel lines to the fittings at the rear of the cylinder head. See Figure 'Cylinder Head Fuel Fitting Locations' .

- On DDEC III/IV engines, record the injector calibration code from the load plate with the proper cylinder location.

- Install the valve rocker cover. Refer to '1.6.7 Pre-installation of Rocker Cover' .

- For one-piece valve rocker cover, refer to '1.6.8 Installation of One-Piece Rocker Cover' . For two-piece and three-piece valve rocker cover, refer to '1.6.9 Installation of Two-Piece and Three-Piece Rocker Covers' .

- Verify repair of electronic unit injector. Refer to '12.7 Engine Run-in Instructions' .

| Generated on 10-13-2008 |